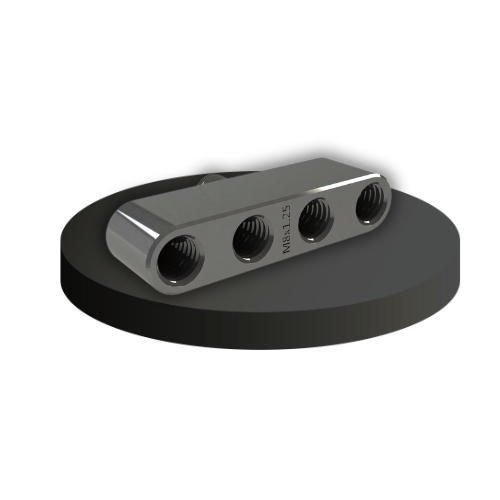

AWC Double Brush Shroud Holder

179 €

The AWC double brush shroud holder serves as a protective accessory for brushes. This adjustable attachment is designed to significantly extend the lifespan of brushes, enhancing their durability and utility. The double brush shroud holder protects two brushes. It was created to combine with a double brush holder.

Product description

Utilizing an AWC Double Brush Shroud Holder with carbon-made brushes in the electrochemical process of cleaning stainless steel welds offers several key benefits:

- Enhanced Efficiency and Precision:

- The Double Brush Shroud Holder allows precise control over brush contact and pressure during electrochemical cleaning. This enhances efficiency by ensuring optimal contact with the stainless steel welds, effectively removing contaminants.

- Improved Durability of Brushes:

- By providing support and protection, the shroud holder significantly extends the lifespan of carbon-made brushes. This leads to reduced replacement frequency and lowers maintenance costs, contributing to a more cost-effective cleaning process.

- Consistent and Uniform Cleaning Results:

- It helps maintain a consistent and uniform pressure on the brushes across the stainless steel welds. This results in a more even cleaning process, ensuring a uniform appearance and surface finish after cleaning.

- Enhanced Safety and Operator Comfort:

- The shroud holder enhances safety by securely holding the brushes in place, reducing the risk of accidental slippage or dislodging during the electrochemical cleaning process. It also provides a comfortable grip for the operator, promoting safe and efficient operation.

- Optimized Resource Utilization:

- By prolonging the lifespan of carbon-made brushes, the shroud holder optimizes the utilization of resources. It minimizes the frequency of brush replacements, reducing the amount of material waste and contributing to a more sustainable and environmentally friendly cleaning process.

In summary, using a Double Brush Shroud Holder with carbon-made brushes in the electrochemical cleaning of stainless steel welds enhances efficiency, prolongs brush life, ensures consistent cleaning results, improves safety, and optimizes resource utilization, making it a valuable tool for the electrochemical cleaning process.